Trying to understand the world of 3D printing can be a confusing and frustrating process. This slows progress and kills creativity - we are on a mission to change that.

(You probably have a lot of questions…)

FAQs

-

Yes! Although, some files are not quite ready for 3D-printing, so we may need to make some adjustments to it prior to printing.

-

Typical project timelines range from 2 weeks to 2 months. Most basic 3D-printing work is completed within a couple weeks. Design and prototyping projects takes a little longer.

-

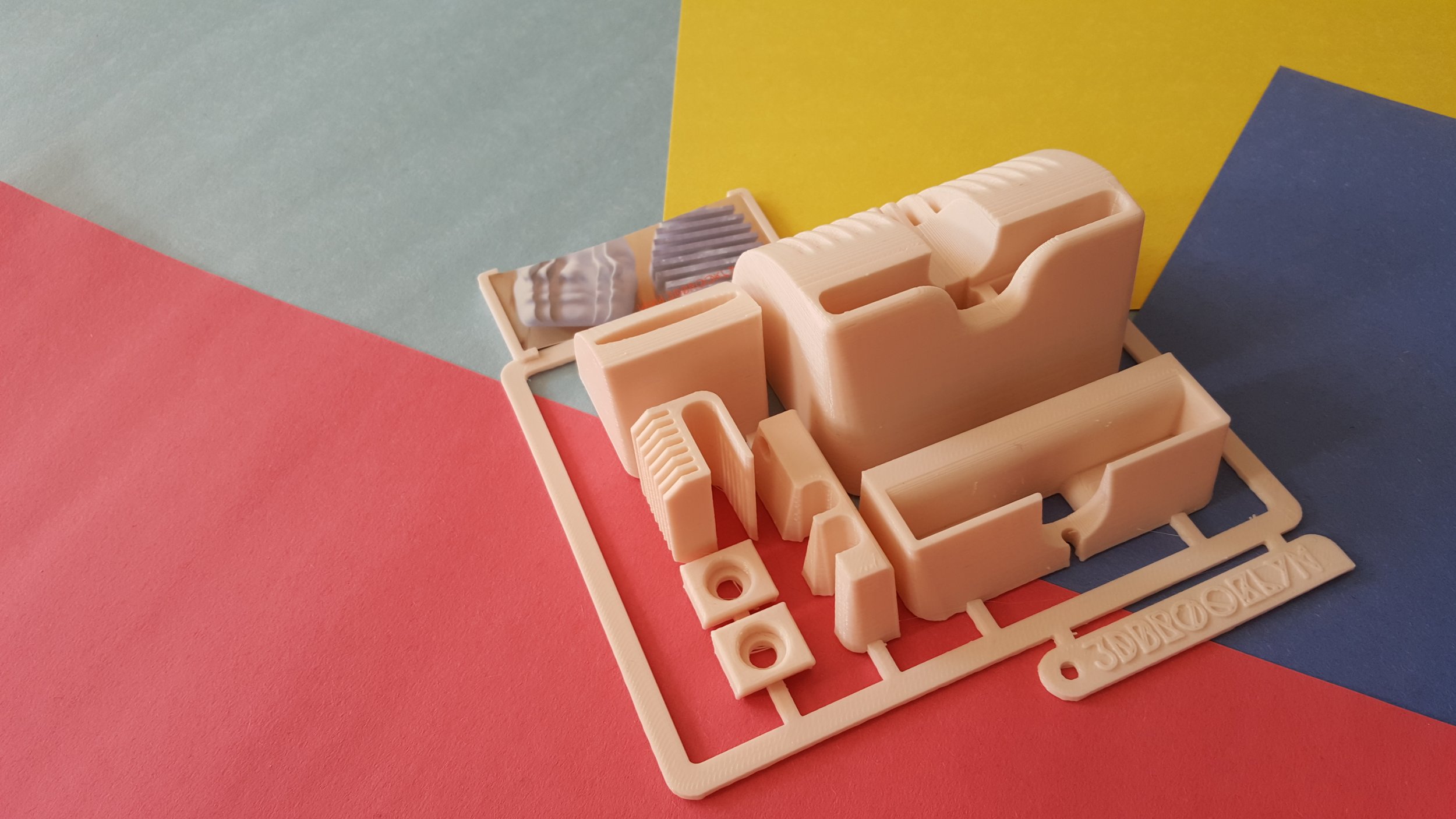

We use PLA bioplastic (polylactic acid) for most of our prototyping work. But we also work with many other plastics, woods and metals.

-

Most projects cost in the $1000-$5000 range. We will generate a quote upfront before beginning any work.

-

Yes, although that may require additional costs depending on how busy we are.

-

Absolutely. We can review and sign yours or we can use our Standard Mutual NDA.

-

We can start from anywhere, really. Most clients send us drawings or references of similar products, shapes, etc. Some clients show us what we call a “home depot” prototype - something they made by hand to get the idea out of their heads (we love these!).

-

In the end, you will walk away with the final physical prototype (approved by you) and all of the 3D designs that we made for you.

-

Yes we can. The most common next steps are: making additional units of approved prototype, making a more polished “looks-like” prototype, creating renderings for a website or pitch deck, sending the 3D files to manufacturers and/or prepping the designs for a patent application. We have a ton of experience in all of these areas.

-

Yes, we have a curated network of manufacturers who are great resources - especially if you are interested using 3D printers to manufacture your product here in the U.S. - that’s our sweet spot!

-

We offer Virtual Meetings and In-person meetings can be arranged if necessary.

-

95% of our prototypes are made with PLA bioplastic, but sustainability is a complicated issue. There are challenges to recycling or composting PLA here in New York City, but we still believe it’s a better option than using oil-based plastics like ABS or PET. We also are big fans of using recycled plastics and are happy to discuss options with you. Regarding sustainability, it is also important to keep in mind that 3D-printing, because it’s an additive manufacturing process, really minimizes material waste compared to more industrial manufacturing processes like die-cutting or CNC milling.

-

Most of our prototypes fall into one of these three categories: Draft Prototype (very basic), Functional Prototype (making sure things are working properly) or Aesthetic Prototype (making it look like it came off a shelf in a store).

-

If you are looking for 3D printer repair service nearby for desktop machines, your search continues - we don’t offer that service. Your best bet is a good ol-fashioned YouTube binge or maybe Chat GPT can help! However, if you have an industrial 3D printer contact CADBlu to see if they can help. Good luck!

-

Yes! Contact us to discuss your project!

“The entire 3D Brooklyn team was such a pleasure to work with. They walked me through the process step by step (this was my first experience with 3D printing) and kept me updated of progress along the way. I look forward to working with them again!”

-Liza W.